هاتف

:+86 18924298409

هاتف

:+86 18924298409 بريد إلكتروني

:info@gftrusses.com

بريد إلكتروني

:info@gftrusses.com

ما هو نظام دعم الجدار بتقنية LED؟

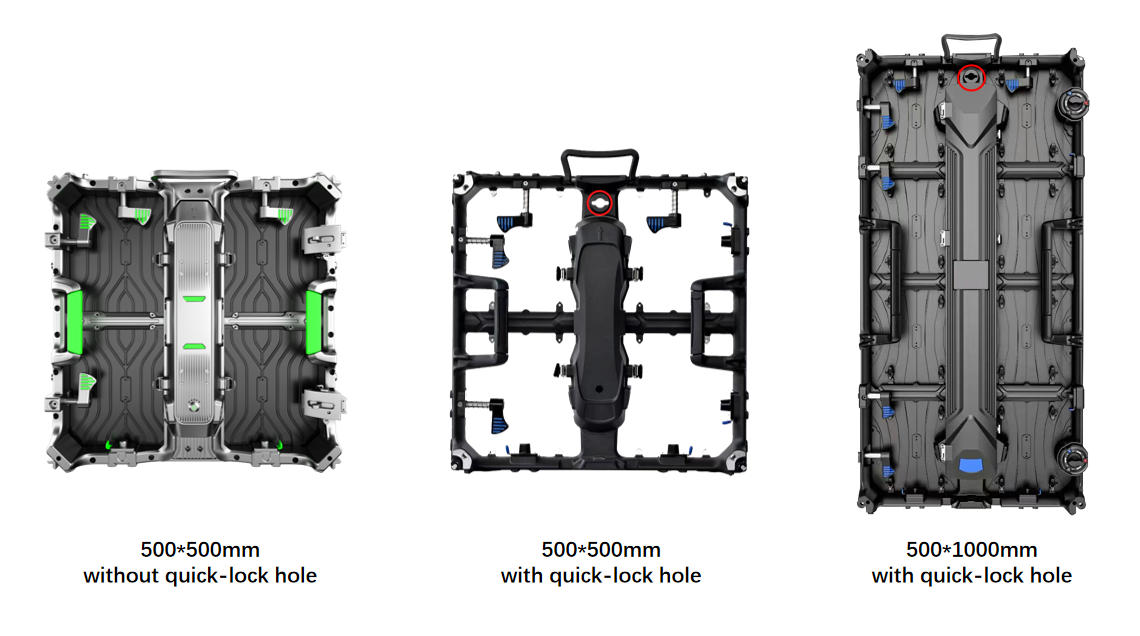

نظام دعم الحائط الأرضي لشاشات LED هو نظام يُستخدم لدعم شاشات العرض LED. وهو مناسب لشاشات LED بأحجام 500*500 مم، و500*1000 مم، و640*640 مم، و640*480 مم، و960*960 مم، وغيرها من المواصفات.

1. التحضير قبل التثبيت

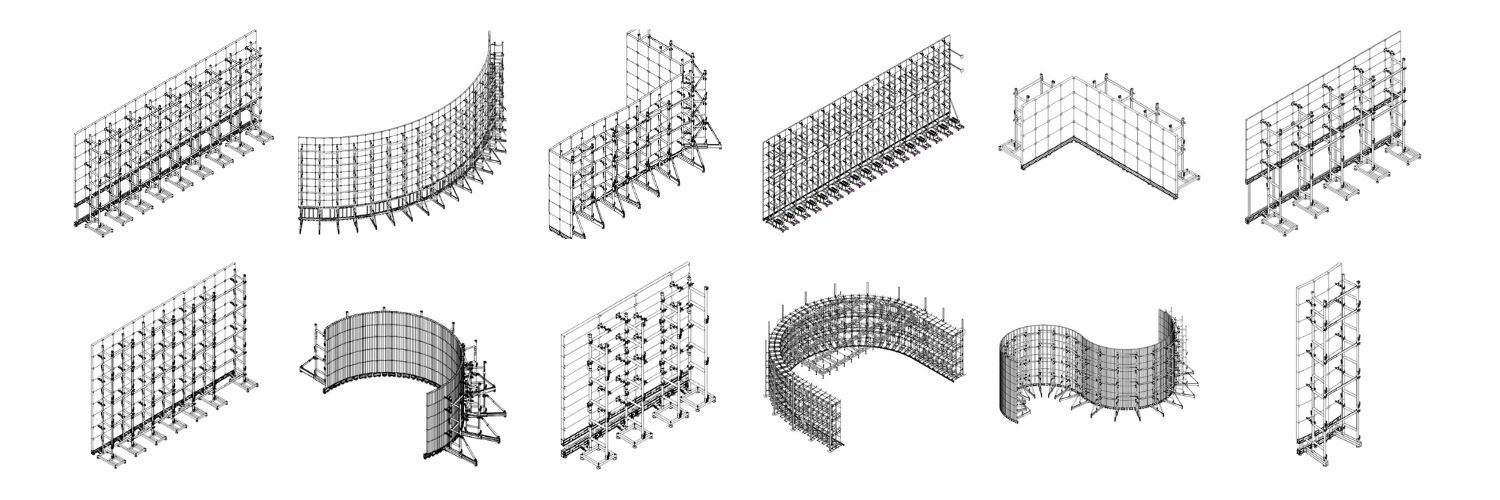

أولاً، عليك التأكد مما إذا كان جدار LED الخاص بك سيُستخدم على الأرض أم في مكان مرتفع. ثم هل لوحة LED الخاصة بك عبارة عن لوحة شاشة مستقيمة أم لوحة شاشة منحنية؟ لدينا مستقيم حامل جداري LED, دعامة أرضية جدارية LED مستقيمة معلقة على الأرض, حامل أرضي جداري منحني مزود بإضاءة LED، و دعامة أرضية منحنية لجدار LED معلق على الأرضلتختار من بينها.

بعد ذلك، يجب التأكد من استواء موقع التركيب، والتحقق من وجود أي مناطق غير مستوية أو أرض رخوة. تؤثر ظروف الأرض المختلفة بشكل مباشر على استقرار هيكل جدار شاشة LED. في الوقت نفسه، من الضروري الانتباه إلى وجود عوامل خطر محتملة مثل المنحدرات ومصارف المياه في الموقع. بالنسبة للبيئات الخارجية، يجب أيضًا مراعاة تغيرات الطقس. من خلال مسح ظروف الموقع مسبقًا، يمكن تقليل مخاطر التركيب بشكل فعال وضمان سلامة واستقرار الهيكل أثناء الاستخدام.

لا تتمتع الأراضي العشبية أو الرملية أو الرخوة عادةً بقدرة تحمل كافية. إذا تم تركيب دعامة جدارية LED مباشرةً على هذه الأراضي، فمن السهل جدًا أن تميل أو حتى تسقط تمامًا. خاصةً في المناطق التي تهب فيها رياح قوية أو يكثر فيها النشاط البشري، فإن ذلك يُشكل مخاطر خفية على السلامة في الموقع. لذلك، في مثل هذه الظروف الأرضية، يجب اتخاذ تدابير تدعيم إضافية باستخدام دعامة جدارية LED ذات قاعدة أكبر. على الأسطح المناسبة (مثل الخرسانة)، استخدم مسامير تثبيت كيميائية أو مسامير تمدد لتثبيت القاعدة مباشرةً. أما في المواقع التي لا تستوفي متطلبات السلامة، فينبغي تجنب البناء.

يشير الارتفاع المكاني إلى المساحة الخالية من العوائق الموجودة أعلى الشاشة (مثل عوارض السقف، والأسقف المعلقة، ووحدات الإضاءة، وأنابيب الحريق، وأنابيب التهوية). يجب توفير مساحة تشغيل آمنة وكافية (يوصى عادةً بأن يكون الجزء العلوي من الشاشة على بُعد 0.8 متر على الأقل أسفل أي عائق) لتسهيل رفع الألواح، وتركيبها، والصيانة اللاحقة. أما قيود الامتداد فتشير إلى المسافة بين جوانب الشاشة والجدران أو الأعمدة أو أي تجهيزات أخرى. وهذا يحدد ما إذا كانت مسارات التركيب والنقل خالية من العوائق، وما إذا كان من الممكن وضع لوحة الشاشة بسلاسة. في الوقت نفسه، من الضروري مراعاة توفير قناة إصلاح خلف الشاشة (يوصى بأن يكون عرضها 0.8 متر على الأقل).

تأكد من موردي ألواح الشاشة لديك لمعرفة ما إذا كانت الألواح التي اشتريتها مزودة بفتحات قفل سريع. إذا كانت مزودة بها، يمكنك تزويدنا برسم تخطيطي للوح. بإمكان GF-Truss تخصيص القفل السريع ليناسب لوحك. في حال عدم وجود فتحة قفل سريع، يمكنك استخدام أقفال لولبية.

2. اختيار نظام دعم جدار LED المناسب

بالنسبة لشاشات العرض المستقيمة، نوفر دعامات أرضية جدارية مستقيمة وأخرى معلقة. أما بالنسبة لشاشات العرض المنحنية/شاشات OLED، فنوفر دعامات أرضية جدارية منحنية، ودعامات أرضية جدارية منحنية معلقة، ودعامات أرضية مرنة. بالإضافة إلى دعامات شاشات LED، تتوفر أيضًا عوارض تعليق لشاشات LED من GF-Truss.

الحل القياسي: مناسب لتركيبات الأحجام الشائعة (مثل دعامة جدارية مستقيمة لمصابيح LED بمقاس 5×3 أمتار)، والأسطح المنحنية القياسية، والارتفاعات العادية. يتميز الحل بسرعة التوصيل وتوفر ملحقات متعددة الاستخدامات.

حلول مخصصة: أمر لا بد منه في الحالات التالية:

1.حجم مادي خاص: مساحة كبيرة للغاية، قطع ذو شكل خاص، مطابقة مستقيمة ومقوسة.

2.الحمل أو المدى الأقصى: يتجاوز نطاق الأمان لجدول الأحمال القياسي.

عندما يكون جدار LED كبيرًا وارتفاعه الإجمالي مرتفعًا (أكثر من 5 أمتار)، أو عند استخدامه في بيئات خارجية عاصفة، فمن الضروري عادةً تركيب قاعدة أكبر، أو ثقل موازن إضافي. يُحسّن هذا النوع من الهياكل بشكل فعّال من قدرة الجدار على مقاومة الانقلاب ويقلل من خطر عدم استقراره الهيكلي الناتج عن القوى الخارجية. ويُعدّ تصميم الثقل الموازن المناسب، خاصةً في المواقع ذات الظروف الأرضية المحدودة أو التي يتعذر تثبيت الجدار فيها، وسيلةً مهمةً لضمان السلامة.

3. عملية التثبيت خطوة بخطوة

بحسب حجم جدار LED، رتب العوارض الأرضية بالتسلسل. اربط العوارض الأرضية المتجاورة معًا، ثم ثبّت القواعد القابلة للتعديل عليها. استخدم ميزانًا للتأكد من استواء العوارض الأرضية. اضبط القواعد والعوارض الأرضية بدقة باستخدام الأرجل القابلة للتعديل لتعويض أي مناطق غير مستوية، وذلك لضمان استواء وثبات هيكل الأساس بالكامل.

قم بتركيب دعامات السلم من الطبقة الأولى على القاعدة. وفقًا للارتفاع المصمم، قم بتركيب طبقات دعامات السلم اللاحقة بالتتابع. اربط دعامات السلم المتجاورة بالعوارض/العوارض التلسكوبية لتجنب اهتزاز الهيكل.

بعد تركيب دعامات السلم، يمكن تثبيت ألواح شاشة LED. أولاً، استخدم قفل الألواح الموجود على العارضة الأرضية لتثبيت الطبقة الأولى من الألواح بإحكام. ثم قم بتركيب الألواح طبقة تلو الأخرى من الأسفل إلى الأعلى، مع مراعاة المحاذاة والاستواء بين الألواح أثناء التركيب.

قم بتوصيل القفل السريع/قفل البرغي بعوارض السلم أولاً، ثم قم بتثبيت الألواح. بعد وضع الألواح في مكانها، قم بتثبيتها بدورها. أثناء التثبيت، من الضروري التأكد من أن الموصل مثبت بإحكام في مكانه لمنع تحرك اللوح أو اهتزازه أثناء الاستخدام.

بعد إتمام جميع أعمال التركيب، سيتم فحص الهيكل بالكامل فحصًا دقيقًا، بما في ذلك العوارض الأرضية، والقواعد القابلة للتعديل، والهياكل السلمية، والعوارض المتقاطعة، ونقاط توصيل الألواح. يجب التأكد من إحكام ربط جميع الموصلات، ومن عدم وجود أي حركة أو خلل ملحوظ في الهيكل. وبناءً على ظروف الموقع وحجم الشاشة، ينبغي إجراء عمليات تقوية ضرورية في الأجزاء الرئيسية لضمان سلامة النظام واستقراره على المدى الطويل أو في البيئات المعقدة.

4. أخطاء شائعة في التركيب يجب تجنبها

تُعدّ حالة الأرض من العوامل الرئيسية التي تؤثر على سلامة هياكل دعم شاشات LED الأرضية. فإذا تم تركيب الهيكل مباشرةً دون تقييم دقيق لمستوى الأرض واستقرارها، فمن السهل حدوث توزيع غير متساوٍ للأحمال عند القاعدة. وعندما تكون الأرض غير مستوية أو مائلة أو عرضة للهبوط، يميل الهيكل إلى الأمام، مما يؤثر سلبًا على استقرار الشاشة ويزيد من مخاطر السلامة بشكل كبير. لذا، يجب فحص الأرض ومعالجتها حسب الحاجة قبل التركيب، مع استخدام أوزان موازنة مناسبة أو اتخاذ تدابير تثبيت إضافية عند الضرورة.

يُعدّ عدم ضبط مستوى عوارض وقواعد الأرضية بدقة مشكلة شائعة أخرى، ولكنها تُغفل بسهولة. فإذا لم تكن القاعدة مستوية، سيتفاقم الخطأ باستمرار أثناء التركيب، مما يؤثر بشكل مباشر على دقة تركيب لوحة شاشة LED ووحدتها. وقد ينتج عن ذلك عدم محاذاة، أو فواصل غير متساوية، أو قوى موضعية بين الألواح. لذا، يجب استخدام أدوات احترافية لضبط المستوى بدقة أثناء التركيب الأولي لتوفير أساس متين لتركيب سلس.

5. الفحص والصيانة بعد التركيب

يلزم إجراء فحص شامل للسلامة قبل بدء استخدام النظام. ويشمل ذلك التحقق من استواء لوحات شاشة LED وتوصيلها بإحكام، والتأكد من عدم وجود أي حركة أو إزاحة، ومن فعالية جميع أجهزة قفل الأمان.

للاستخدام طويل الأمد أو المشاريع التي تتطلب تفكيكًا متكررًا، يُنصح بوضع خطط فحص وصيانة دورية. ينبغي التركيز على هيكل الدعم الأساسي، والوصلات، والأجزاء التي تتحمل قوى عالية التردد، مع إجراء عمليات الشد والتعديل أو استبدال المكونات البالية عند الحاجة. قبل كل عملية نقل أو إعادة تركيب، يمكن أن تساعد إعادة التسوية والفحص الهيكلي في تقليل مخاطر الإجهاد الهيكلي، وإطالة عمر الخدمة، وضمان الاستقرار على المدى الطويل والتشغيل الآمن.

6.لماذا تختار GF-Truss

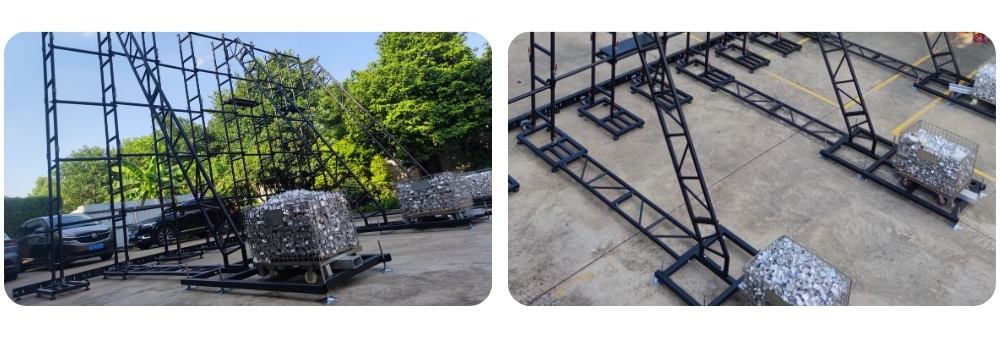

تُعدّ GF-Truss شركة رائدة في مجال هياكل سبائك الألومنيوم ودعامات جدران LED الأرضية منذ سنوات عديدة، وقد راكمت خبرة عملية واسعة في مشاريع متنوعة، تشمل المعارض الداخلية، والعروض الخارجية، والفعاليات الرياضية، والمؤتمرات الصحفية، والجولات الفنية. كما تُعتبر GF-Truss شريكًا استراتيجيًا طويل الأمد لشركات تصنيع شاشات LED في الصين. يُقدّم فريق التصميم لدينا أكثر من 2300 حل مُخصّص للعملاء سنويًا. وبفضل مشاركتنا في مشاريع جدران LED مُختلفة الأحجام والارتفاعات وطرق التركيب، نتمتع بفهم عميق لسلوك الأحمال الهيكلية، وعملية التركيب، والمخاطر في الموقع. وهذا يُساعدنا على تجنّب المشاكل المُحتملة وتوفير أساس دعم أكثر موثوقية لمشاريعكم.

تُقدّم GF-Truss حلولاً مرنة ومخصصة تناسب مختلف ظروف المواقع، وأحجام الشاشات المتنوعة، ومتطلبات التطبيقات. سيشارك فريقنا الفني في المشروع، وسيعمل بتعاون وثيق مع العملاء ومنظمي الفعاليات. نجري تقييماً شاملاً للعوامل الرئيسية، مثل أبعاد المكان، وظروف الأرض، وهيكل السقف. وبناءً على معلومات تفصيلية من الموقع، سنقدم مجموعة كاملة من الاقتراحات الاحترافية وخطط الجدوى، بدءاً من اختيار الهيكل، وتحديد الحجم، وتصميم الوصلات.

تتميز حلول الدعم الأرضي لجدران LED من GF-Truss بتعدد استخداماتها، وتصميمها المعياري، وقابليتها للتوسع. فهي تتكيف على نطاق واسع مع مختلف سيناريوهات الأنشطة واحتياجات التطبيقات طويلة الأجل. بالنسبة للفعاليات المؤقتة، مثل المهرجانات الموسيقية، وإطلاق المنتجات، والمعارض التجارية، يتميز نظامنا بسهولة الفك والتركيب، وكفاءة النقل، ومرونة إعادة التنظيم، مما يجعله مناسبًا للجداول الزمنية الضيقة والتغييرات المتكررة في المواقع. أما بالنسبة للمنشآت الثابتة طويلة الأجل، مثل المسارح، والصالات الرياضية، والاستوديوهات، فإننا نركز على الاستقرار والمتانة القصوى للهيكل لتوفير دعم دائم وموثوق. وبالنسبة لمشاريع الجولات الفنية عالية التردد، يتم تعزيز النظام من حيث المتانة، والتوحيد القياسي، وسرعة النشر لضمان استقرار الأداء، مع تقليل تكاليف الخدمات اللوجستية والعمالة بشكل كبير.

7. الحصول على دعم احترافي

سواء كنتم بصدد تطوير فكرة أولية، أو مقارنة الحلول، أو وضع اللمسات الأخيرة على تصميم مفصل، فإن شركة GF-Truss على أتم الاستعداد لدعم مشروعكم. ندعوكم لمشاركة مخطط مشروعكم، وبيانات الموقع، وأفكاركم الإبداعية، ليتمكن مصممو الهياكل المحترفون لدينا من تقديم تحليل أولي معمق ونصائح فنية مصممة خصيصًا لتلبية احتياجاتكم. من الفكرة الأولية وحتى التنفيذ النهائي، سنكون شريككم الفني الموثوق.

بناءً على احتياجاتكم المحددة، سيقوم فريق التصميم لدينا بإجراء حسابات هيكلية وتحليلات محاكاة دقيقة لتطوير حلول هيكلية احترافية ومخصصة، مصحوبة بعرض سعر واضح وشفاف للمشروع. نضمن لكم أن كل مخطط قد خضع لفحص دقيق لضمان السلامة، وأن كل عرض سعر دقيق ومعقول لضمان حصولكم على معلومات شاملة ودقيقة قبل اتخاذ القرار.

ابدأ استشارة مشروعك الحصرية الآن! يمكنك التواصل معنا عبر واتساب والبريد الإلكتروني للحصول على حلول تقنية مجانية وعروض أسعار دقيقة.

ترك رسالة

مسح ضوئي إلى WhatsApp :

Hi! Click one of our members below to chat on